Price

Distribution channels

Cross selling

Customer centric

Price elasticity

Sales index

Pricing AI

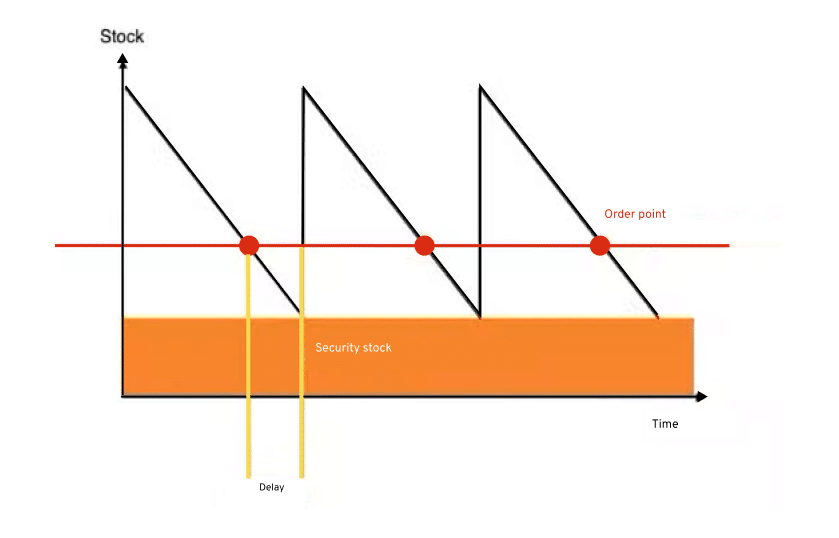

Are you looking to determine the optimal inventory to best support your service? Then you need to understand everything about safety stock! This article provides a detailed explanation of what safety stock is, its importance, how to calculate it, and how to determine the best approach. Want to master the language of pricing? We break down all the important concepts here. Many retailers maintain inventory to meet regular demand and avoid extended delays. These inventories may include all product ranges or focus on highly demanded items. However, even with sufficient stock to fulfill orders on time, unforeseen events or market conditions can disrupt regular operations and jeopardize stock levels. To mitigate such risks, businesses often implement safety stock. Also known as buffer stock, safety stock helps prevent stock outs caused by external fluctuations. It is part of a broader strategy to account for market and demand fluctuations. While it is impossible to predict every variation, it’s helpful to anticipate potential risks that could affect your retail sector. Both retailers and suppliers should consider safety stock, as both are vulnerable to different uncertainties that could affect their operations. For retailers, especially in large-scale distribution, it ensures continuous service. For suppliers, safety stock is even more crucial since a total production halt could be disastrous. As mentioned, safety stock serves as a defense against external uncertainties, which can be divided into two main categories: product-related uncertainties and demand-related uncertainties. These uncertainties are numerous and can occur unexpectedly. They include: Given the high level of unpredictability, businesses must be prepared to act accordingly in all situations. Safety stock acts as a cushion during these periods, preventing shortages or overstocking while waiting for normal conditions to resume. This is even more common if you produce or import goods from abroad, where multiple uncertainties can arise simultaneously. Market and demand fluctuations can also cause uncertainty since customer preferences are often volatile. Demand for one of your products might suddenly surge or drop in a short period. Safety stock allows you to adjust quickly to such changes. These fluctuations can be triggered by media coverage, current events, climate anomalies, competitors’ promotions, or seasonality. Such factors make it crucial to have buffer stock to handle these variations. Although safety stock may seem like the perfect solution to unexpected events, it also presents risks. Holding a portion of your inventory comes with costs and potential challenges. Safety stock should not compensate for poor logistical planning. If issues are recurring, they should be addressed at their root; safety stock should only cover unexpected events. Otherwise, it could exacerbate existing structural problems. Additionally, large safety stock levels can increase storage costs. The more products you hold, the more you will pay for warehousing, maintenance, transport, and storage. Improper use of safety stock can create a vicious cycle that worsens problems rather than resolving them. Dependency on safety stock could make you more vulnerable to external factors rather than protecting you from them. Therefore, balancing your logistics and commercial strategy is essential. When determining safety stock in retail, it’s crucial to account for various elements that influence both demand and supply uncertainties. Striking the right balance ensures you can meet customer needs while minimizing risks of stockouts or excess inventory. While storing products can be expensive, as it ties up cash without immediate returns, it’s essential to think long-term. These short-term losses might be necessary for securing higher margins later. Missing sales due to stockouts or shortages can harm your revenue and brand image. You need to weigh opportunity costs—the potential earnings from meeting unexpected demand—against storage costs. If opportunity costs are higher than storage costs, you can increase safety stock; otherwise, you may want to reduce it. Not all products are exposed to the same risks. Differentiate your products based on how external factors affect demand. For items with highly variable demand, maintaining a higher safety stock is advisable. Do not apply a single safety stock strategy across all product categories; tailor it to each product’s characteristics. Your sector and brand reputation will influence customer expectations for service levels. Safety stock should align with those expectations. If you promise one-day delivery, your safety stock strategy will differ from a smaller business with flexible delivery terms. Failing to meet delivery promises can damage customer trust, hurt your brand image, and lead to lost market share. Calculating safety stock is crucial for meeting customer demand despite supply chain variability, preventing stockouts, and balancing inventory to optimize service while minimizing excess stock and costs. In most cases, safety stock is not applied across the entire product catalog. Businesses often use the Pareto principle to identify which products to focus on. This principle suggests that 80% of a business’s results come from 20% of its products or services. This approach categorizes products into three groups: A, B, and C, based on their value relative to the total inventory. Meet one of our pricing experts Advances in forecasting tools modern solutions now offer more accurate methods for forecasting sales and calculating safety stock, moving beyond traditional formulas. These tools take into account real-time data and advanced analytics, allowing for more precise stock management, minimizing risks, and adapting to fluctuations in demand. Despite the advancements, several basic approaches are still commonly used: Once you’ve calculated your safety stock, the next key calculation is the order point. The order point, also known as the reorder point, is the threshold at which you need to replenish stock. It sits just before the safety stock and acts as an alert for when to restock. To ensure profitability and avoid stockouts that hurt sales and brand image, consider using a pricing solution that incorporates artificial intelligence (AI). AI-based pricing solutions, like those offered by PricingHUB, continuously assess market conditions, product elasticity, and stock levels to provide real-time price adjustments based on your commercial objectives. This ensures that pricing strategies are optimized according to stock variations, helping to maintain optimal safety stock and pricing strategies. To learn more, request a free demo with one of our experts. Safety stock acts as a safeguard against delays in the supply chain, helping retailers avoid empty shelves and maintain customer satisfaction even when shipments are late or suppliers face issues. It’s essential for ensuring continuity in retail operations. Retailers should consider demand variability, lead time fluctuations, supplier reliability, and product criticality. Balancing these factors helps set safety stock levels that minimize costs without risking stockouts that can hurt sales and brand reputation. Safety stock allows retailers to maintain consistent product availability, supporting pricing strategies that avoid sudden discounting due to shortages. Adequate buffer stock helps sustain price integrity and customer trust by preventing forced clearance sales or lost sales opportunities. Retailers often maintain higher safety stock for high-demand or critical items, while applying leaner inventory levels for slow-moving or seasonal products. This category-based approach helps optimize inventory investment and pricing strategies across diverse merchandise. Retailers optimize safety stock by leveraging accurate demand forecasting, supplier performance data, and dynamic inventory adjustments. This minimizes excess stock costs while ensuring enough availability to uphold pricing strategies and maximize profitability. Discover all our pricing glossary articles Calculating a margin Omnichannel Relative price Meet one of our pricing experts Everything You Need to Know About Safety Stock

What is Safety Stock?

Why Implement Safety Stock?

Product-Related Uncertainties

Demand-Related Uncertainties

Risks of Safety Stock

Key Factors to Consider When Determining Safety Stock

Storage Costs vs. Opportunity Costs

Levels of Uncertainty

Service Level Expectations

How to Calculate Safety Stock

Pareto Principle and ABC Method

Discover the benefits of Machine Learning in our Pricing strategies

ABC Categories with Pareto Principle:

Various Calculation Methods

Order Point

Using AI for Pricing and Inventory Management

Frequently Asked Questions (FAQs)

What strategies can retailers use to optimize safety stock without hurting pricing or profitability?

Back margin

Front margin

Gross margin

Sales margin

Net margin

MSRP

Price bundling

Selling price

Psychological price

Price image

Safety stock

Brand rate

Up selling

Yield management

Dynamic pricing Evaluate the potential of price elasticity on your business